In the 50’s, everything from timesheets to invoices to newspapers were printed letterpress. So why is letterpress so expensive now?

The answer is pretty simple: scarcity.

When letterpress was the standard way of printing, there were letterpress presses and skilled operators everywhere.

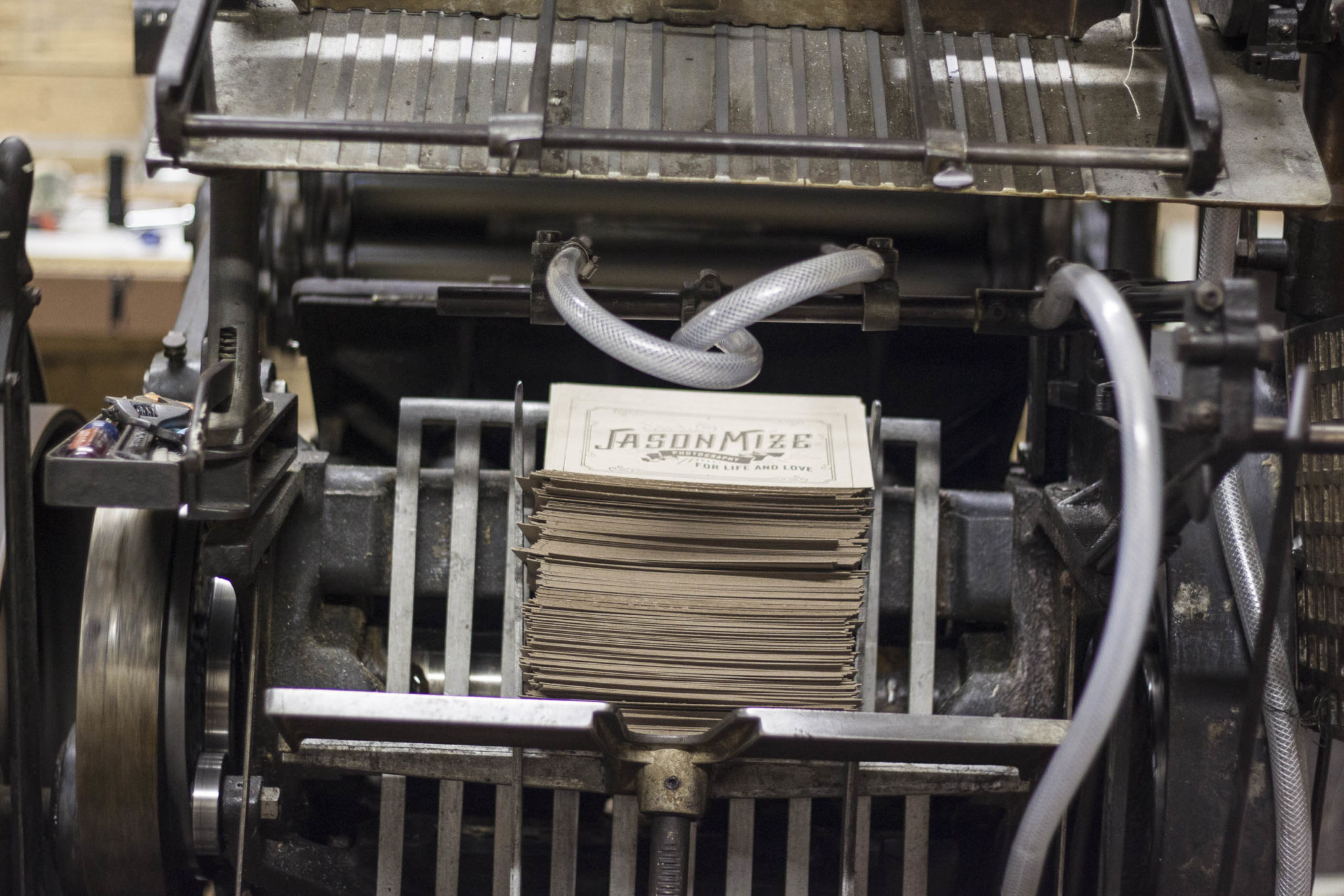

Then offset printing outpaced the quality and speed of letterpress and, by 1985, the last heidelberg windmill (my press of choice) rolled off the production floor.

That means that:

the newest letterpresses available are already 30 years old!

Availability of Presses

So, there are no new presses being made – that means we’re limited to what’s already been produced.

I know it’s hard to believe, but there was a pretty serious period of time (mostly the 90’s) where letterpress just wasn’t cool. During the 90’s print shops were literally throwing away presses (especially older hand-fed models) or selling them for scrap!

Those that remained were used for the things offset presses couldn’t do – variable numbering (those red ID numbers on a form) and diecutting. Many shops irreparably damaged their presses for printing with ink because all they needed them for was diecutting.

So, not only are we limited to what has already been produced – we’re limited to what was produced and not ruined or thrown away.

Availability of Parts

So, these presses are already 30-100+ years old. They’re antiques. To continue using them requires maintenance and replacement of parts, many of which aren’t being manufactured either.

There’s a lot of metal-on-metal movement on these presses. That creates wear that needs repaired. Like a lot of old machines, there are less mechanics willing to do this work (who makes machines out of cast iron anyway?!)

Education

It used to be possible getting a real trade apprenticeship as a printer. That’s not really an option now, especially in letterpress. There just isn’t the huge culture of learning this craft, though there is a small, wonderful group of printers more than willing to help one another out and keep the trade alive.

Scale

Commercial printers are used to working in scale. Printing direct mail or college catalogues or magazines usually puts the quantities in the tens of thousands.

Letterpress projects are often 100 pieces or 500 pieces.

Because much of the cost of printing is in setup, smaller runs will invariably cost more per-piece than larger runs. I tell people the first one usually costs a couple hundred. Each additional print is often pennies.

Paper Costs

If every client wanted 30# copy paper for their letterpress project, it would be cheaper. But who in sam hill wants that?

We want thick, luxurious cotton stocks! Things that take a deep impression. Do you realize how expensive that stuff is? It’s a major factor in the cost of letterpress.

When I work with offset printers on projects with combined processes, their eyes go big as saucers when we talk paper selection – these papers are often 4-10x the cost of the stocks they usually use.

[hr align=”center”]

Letterpress isn’t cheap. And time is not our friend when it comes to price (unless someone gets really serious about producing a viable new press).

As long as these presses run, there will be people like me happy to turn beautiful art into stunning prints.

Lots of great points 🙂 I’ve broken my press twice—it’s so heartbreaking!